BME494s2013 Project Team1: Difference between revisions

No edit summary |

|||

| Line 39: | Line 39: | ||

<br> | <br> | ||

This technology will prove to be very helpful for hunters or those who are outdoors for they will not have to worry about disposing of their light source. Used like a regular glow stick, the different components of the device will remain separated and will be mixed together to produce light once a certain amount of force is applied. | This technology will prove to be very helpful for hunters or those who are outdoors for they will not have to worry about disposing of their light source. Used like a regular glow stick, the different components of the device will remain separated and will be mixed together to produce light once a certain amount of force is applied. | ||

| Line 70: | Line 67: | ||

<br> | <br> | ||

This means that if glucose and lactose are available for the cell, transcription will occur but at a slow rate. Obviously, if there is no lactose at all, nothing will be transcribed. As long as lactose is available, transcription will happen as the LacI repressor is never binded to the operator. Thus, when these Lac proteins are made with the presence of lactose, the lac gene and its derivatives can be used to trigger a color change within the cell. Once glucose is used up, lactose acts as the power source, and the lac operon can truly act as a reporter gene. As in the case for our group, the lac operon device contained the necessary promoters, ribosome-binding sites, terminators, a LacI repressor, a cyan fluorescent protein, and a vector backbone based on the Type IIS assebmly strategy and would turn a bright cyan color when exposed to lactose. This "switch" function can have a multitude of possibilities, and one of these uses is focused on in the page. | This means that if glucose and lactose are available for the cell, transcription will occur but at a slow rate. Obviously, if there is no lactose at all, nothing will be transcribed. As long as lactose is available, transcription will happen as the LacI repressor is never binded to the operator. Thus, when these Lac proteins are made with the presence of lactose, the lac gene and its derivatives can be used to trigger a color change within the cell. Once glucose is used up, lactose acts as the power source, and the lac operon can truly act as a reporter gene. As in the case for our group, the lac operon device contained the necessary promoters, ribosome-binding sites, terminators, a LacI repressor, a cyan fluorescent protein, and a vector backbone based on the Type IIS assebmly strategy and would turn a bright cyan color when exposed to lactose. This "switch" function can have a multitude of possibilities, and one of these uses is focused on in the page. | ||

[[Image:LacOperon.jpg|thumb|1040px||center|Basic Components of a Lac Operon <cite>e-coli-wiki</cite>]] | |||

==Design: Our genetic circuit== | ==Design: Our genetic circuit== | ||

Revision as of 18:07, 28 April 2013

Home People Course Projects Course Materials Schedule Photos Wiki Editing Help

|

Overview & PurposeEscherichia coli, commonly referred to as E. coli, has many different strains. The most commonly known serotypes of these bacteria can cause serious food poisoning or even fatality in humans. However, most strains are completely harmless. These strains are usually found in the gut of the host and help by producing K2 and helping with digestion. The presence of these bacteria is very beneficial for it helps to prevent pathogenic bacteria from being present in the intestine.[1]

Background

"Only LacZ and LacY appear to be necessary for lactose catabolism" [3].

Design: Our genetic circuitJulia Our gene switchParts<tab>pSB1A3-1 is a high copy number plasmid. The replication origin is a pUC19-derived pMB1 (copy number of 100-300 per cell). The terminators bracketing pSB1A3 MCS are designed to prevent transcription from inside the MCS from reading out into the vector.

Building: Assembly scheme The assembly strategy employed in the design of this device is a Type IIS assembly strategy. The steps and procedures involved in this single-pot assembly are described below. MutagenesisOne of the parts chosen by our group contains a BsmBI cut site, which would disrupt the digestion and ligation process further along the assembly strategy. In order to counteract this, the part is subjected to mutagenesis to alter a selected base pair within the DNA to eliminate the BsmBI cut site while keeping the integrity of the coding sequence intact. This site-directed base substitution is performed using two primers with centrally located substitution sites to alter the selected base pair on a methylated plasmid. After the part has completed the mutagenesis, the DNA sequence (which is linear at this point in time) undergoes in vitro recombination reaction. The host cell then "circularizes" the mutated part DNA and digests the original methylated plasmid. If the methylation of the original plasmid is skipped, an additional purification step would be necessary to extract the mutated plasmid.[5]

PCRPCR, or polymerase chain reaction, is then used to amplify the DNA sequences and create modular fragments for ease of assembly. A DNA fragment is combined with its forward and reverse primers, nucleotides, and DNA polymerase. This mixture is then inserted into a thermal cycler, which cycles the internal temperature with predetermined values. These changes in temperature cause the DNA to separate, the primers to pair with their respective DNA strands, the DNA polymerase to activate, and a new DNA strand to be formed. The thermal cycling procedure, listed below, is continued until the specified fragment is amplified sufficiently for use. Thermal Cycling

Digestion and ligation reactionThe Type IIS assembly strategy employs a single-pot assembly, wherein digestion and ligation occur in tandem. To prevent the futile digestion/ligation loop that could result from this assembly strategy, the BsmBI restriction enzyme is used. BsmBI is useful in this scenario because its binding site is remote from its cutting site. In the digestion and ligation reaction, BsmBI binds to its binding site, CGTCTC, and cuts at a location further along the DNA strand. This creates a 4 base pair "sticky overhang." Complementary "sticky overhangs" then pair up and are connected by the ligase. The thermal cycling procedure used in the digestion and ligation reaction is shown below. Thermal Cycling

Parts and primersThe following table lists the BioBricks used in the construction of the Sweet Cyan device. The individual parts can be found with a simple search of the part IDs at the Parts Registry.

Testing: Modeling and GFP imaging

A lac switch modelWe used a previously published synthetic switch, developed by Ceroni et al.[6], to understand how our system could potentially be modeled and simulated. The graphic to the left depicts the relationships between the parameters of the lac operon switch described by Ceroni using a network diagram illustration. The parameters shown in the illustration relate to cell processes and could be used in forming a cohesive mathematical model of the cell's operation. In order to approximate the behavior of this set-up, a mathematical model can be developed based upon the relationships between the processes found in the cell. These relationships can be expressed in mathematical terms using numbers that relate to the system, including creation or decay rates, concentrations, or various constants. The actual values for these parameters can be sourced from experimentation, literature, or a predefined steady-state. If a model is well-defined and the necessary parameters known, a person may use the model to ascertain the state of a cell at a given point in time. For example, if an experimenter wanted to know the decay of the GFP protein molecules at a given point in time in a single cell, the following equation could be written using the notation found in the table below. Decay = G × λG/L The formula takes the concentration of the GFP protein in molecules per cell ("G") and multiplies it by the protein degradation rate in minutes-1 ("λG/L"). This results in a decay value for GPF in molecules per minute per cell. The Ceroni et al. model and the network diagram illustration use the table of variables and parameters seen below in their representation of the lac switch. The variables related to a particular cell process are located near to that process in the network diagram illustration.

An interactive modelWe used a model of the natural Lac operon to understand how changing the parameter values changes the behavior of the system. By changing the initial concentration of input (IPTG in this case), we were able to estimate the threshold that produces an "on" state in the system. Initially, the code had the concentration at 0.32 which is seen in the β-galactoside (Bgal concentration) vs. time plot (Figure 1). This value was changed again to 0.25 in determining the threshold that produces this "on" state (Figure 2). After proceeding to go up and down with these a values, a threshold was indeed found where the output concentration of IPTG was sustained and is about 0.064 (Figure 3).

Collecting imperical values to improve the modelSarah

Stakeholder Assessment

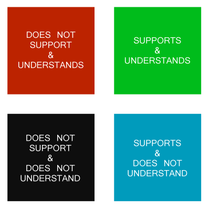

SUPPORTS & UNDERSTANDS Public and laymen knowledge of E. coli may consist of only what they hear in the news, which often relates to food contamination scares; for this reason, stakeholders of the device itself may not support its production if they believe that widespread stigma may prevent successful marketing and sales campaigns. DOES NOT SUPPORT & DOES NOT UNDERSTAND

Our Team

Works Cited |