IGEM:IMPERIAL/2009/The Multi Pill

Feedback page

Potentials of Encapsulation

This article illustrates the potentials of microencapsulation: What's in your microcapsule? Tattoo ink -- and more

Extracts from the article

1. Any fragile, bioactive molecule – proteins, hormones, DNA – can be coated so that it can be safely delivered to where it is needed in the body and still do its job once it gets there.

2. The process is used to make products such as aspirin, plant food, stain remover, and cake mix. It’s even used to make scratch-and-sniff perfume advertisements found in magazines: Scratch the treated paper and microbeads burst to release the scent.

3. Knowing how a particular solid, liquid or gas behaves when exposed to heat, light, water or enzymes is critical to developing the correct coating method that will properly protect a substance until it can be released.

Motivation

There are several problems associated with oral delivery of peptides:

- 1 pill = 1 drug

- High manufacturing cost

- Variable peptide half life

We propose a solution that enables customized drug production

Main features:

- Multiple inputs enable drug selection

- Offers uniformity

- Cheaper & simpler (direct packaging)

- Fresh peptide production

- Dosage control

- Reduced loss of peptide

Current methods for oral peptide delivery

We chose to combine the advantages of using polysaccharide encapsulation and symbiotic microbes.

Other solutions do not consider all the issues that we are addressing:

1) Control of dose

2) Choice of drug

3) Release in the intestine

4) Suitable chassis

5) Peptide delivery: Polysaccharide encapsulation properties

Schematic of our solution:

Operating principle of solution

Functional blocks

Process

1)We insert our symbiotic microbes in an alginate capsule

2)An light trigger:variable input for drug selection will initiate secretion of our choice of drug

3)After a delay (genetic timer) the drug will be expressed, to enable enough time for delivery

4)We are also able to delete the plasmids once protein (drug) is produced

5)This is followed by release (delivery) into the intestine.

Schematic of light selective inputs

4 possible light input combinations (use red and blue light receptors from the biobricks registry):

(1)Red=0,Blue=0: No drug produced

(2)Red=0,Blue=1: Drug 1 produced

(3)Red=1,Blue=0: Drug 2 produced

(4)Red=1,Blue=1: Drug 3 produced

Genetic circuit

Possible Applications

Diagnostic tools for treatment

Nanoparticle Enables Light-Activated Ovarian Cancer Detection and Therapy

Summary

1. photosensitizer that kill cancer cells when irradiated with light.

2. from wikipedia, the definition of a photosensitizer photosensitizer is a drug, food, or other chemical that increases photosensitivity of the organism. This may be an adverse effect of many drugs, or a desired effect in photodynamic therapy of tumors.

3. hypericin is chosen as it can function as both a photosensitizer and a fluorescent marker, such that it can illuminate microscopic metastatic tumors

4. hypericin cells can be detected via fluorescence microscopy, hence enabling surgeons to use nanoparticle-delivered hypericin to find micrometastatic lesions while performing surgery to remove the primary ovarian tumour

Bioremediation

Many species of Pseudomonas are used for Bioremediation. Perhaps a possible application would be to encapsulate them such that they'll be easier to transport???

stolen from wikipedia, a short write up on uses of Pseudomonas for Bioremediation:

Use as bioremediation agents

Some members of the genus Pseudomonas are able to metabolise chemical pollutants in the environment, and as a result can be used for bioremediation. Notable species demonstrated as suitable for use as bioremediation agents include:

- P. alcaligenes, which can degrade polycyclic aromatic hydrocarbons.[1]

- P. mendocina, which is able to degrade toluene.[2]

- P. pseudoalcaligenes is able to use cyanide as a nitrogen source.[3]

- P. resinovorans can degrade carbazole.[4]

- P. veronii has been shown to degrade a variety of simple aromatic organic compounds.[5][6]

- P. putida has the ability to degrade organic solvents such as toluene.[7] At least one strain of this bacterium is able to convert morphine in aqueous solution into the stronger and somewhat expensive to manufacture drug hydromorphone (Dilaudid).

- Strain KC of P. stutzeri is able to degrade carbon tetrachloride.[8]

Biologists? Do they ring a bell???

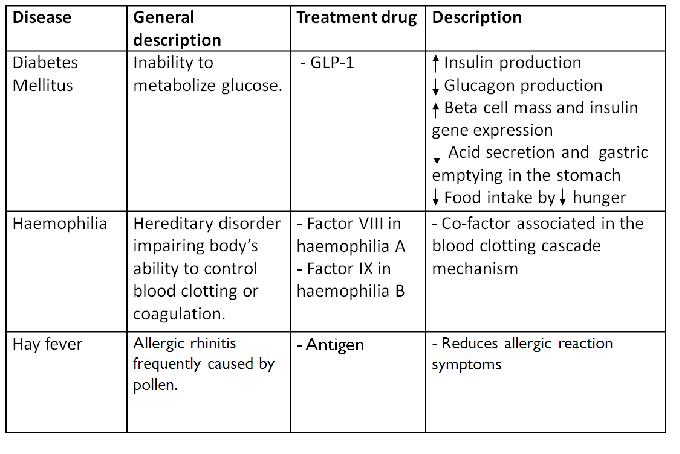

Target common diseases

Other considerations

Choice of chassis

We considered the following factors:

- Non pathogenic strain

- Resting stage

- Sporulation

- Freeze dry

- Cold storage

- Large Biobrick availability

- Expertise in college

General design complications

- Keep bacteria alive

- Keep bacteria metabolically active

- Keep bacteria alive longer than peptide half life?

- Dose control

Modelling:Functional blocks

At this stage, we can split the project into different modelling blocks and analyze them from a conceptual framework.

Slides 17th July

Click here on the link for presentation slides given in todays feedback session.

Presentation Feedback 17th July

PF: Project as a whole is massively ambitious. How much can we actually do?