Work Area

Papers to cite

biosensors

- Daunert S, Barrett G, Feliciano JS, Shetty RS, Shrestha S, and Smith-Spencer W. Genetically engineered whole-cell sensing systems: coupling biological recognition with reporter genes. Chem Rev. 2000 Jul 12;100(7):2705-38. DOI:10.1021/cr990115p |

- Yagi K. Applications of whole-cell bacterial sensors in biotechnology and environmental science. Appl Microbiol Biotechnol. 2007 Jan;73(6):1251-8. DOI:10.1007/s00253-006-0718-6 |

- Harms H, Wells MC, and van der Meer JR. Whole-cell living biosensors--are they ready for environmental application?. Appl Microbiol Biotechnol. 2006 Apr;70(3):273-80. DOI:10.1007/s00253-006-0319-4 |

- Gu MB, Min J, and Kim EJ. Toxicity monitoring and classification of endocrine disrupting chemicals (EDCs) using recombinant bioluminescent bacteria. Chemosphere. 2002 Jan;46(2):289-94. DOI:10.1016/s0045-6535(01)00081-9 |

Papers cited by Forrest's writings

- Huh WK, Falvo JV, Gerke LC, Carroll AS, Howson RW, Weissman JS, and O'Shea EK. Global analysis of protein localization in budding yeast. Nature. 2003 Oct 16;425(6959):686-91. DOI:10.1038/nature02026 |

- Pajot-Augy E, Crowe M, Levasseur G, Salesse R, and Connerton I. Engineered yeasts as reporter systems for odorant detection. J Recept Signal Transduct Res. 2003;23(2-3):155-71. DOI:10.1081/rrs-120025196 |

Biofuel

The need for alternative fuels has increased considerably in the recent years due to rising fossil fuel prices and worldwide attention towards environmental sustainability. While battery technology has steadily progressed, electrochemical energy storage still cannot (and may never) compete with liquid or gaseous fuels on energy density.

Among the promising candidates for alternative fuels are biofuels and hydrogen. Biofuels -- fuels produced from crop-based carbohydrates -- include bioethanol from fermentable corn or switchgrass sugars and biodiesel from plant oils (torney). Numerous groups have employed recombinant and metabolic engineering to develop microorganisms that produce biofuels. For example, a recombinant Saccharomyces yeast strain has been engineered to break down cellulose and ferment ethanol from xylose, a pentose commonly found in renewable lignocellulosic biomass such as waste paper. This was achieved by introducing genes from P. stipitis and S. cerevisiae for their xylose-fermenting ability, and displaying on the cell surface a cellooligosaccharide-degrading fusion protein from an A. aculeatus gene and α-agglutinin (Katahira). Commercial entities pursuing biofuel applications of synthetic biology include California startups Amyris Biotechnologies, LS9, and Synthetic Genomics.

- Torney F, Moeller L, Scarpa A, and Wang K. Genetic engineering approaches to improve bioethanol production from maize. Curr Opin Biotechnol. 2007 Jun;18(3):193-9. DOI:10.1016/j.copbio.2007.03.006 |

- Prasad D, Arun S, Murugesan M, Padmanaban S, Satyanarayanan RS, Berchmans S, and Yegnaraman V. Direct electron transfer with yeast cells and construction of a mediatorless microbial fuel cell. Biosens Bioelectron. 2007 May 15;22(11):2604-10. DOI:10.1016/j.bios.2006.10.028 |

- Okuda N, Ninomiya K, Takao M, Katakura Y, and Shioya S. Microaeration enhances productivity of bioethanol from hydrolysate of waste house wood using ethanologenic Escherichia coli KO11. J Biosci Bioeng. 2007 Apr;103(4):350-7. DOI:10.1263/jbb.103.350 |

- Henstra AM, Sipma J, Rinzema A, and Stams AJ. Microbiology of synthesis gas fermentation for biofuel production. Curr Opin Biotechnol. 2007 Jun;18(3):200-6. DOI:10.1016/j.copbio.2007.03.008 |

- Katahira S, Mizuike A, Fukuda H, and Kondo A. Ethanol fermentation from lignocellulosic hydrolysate by a recombinant xylose- and cellooligosaccharide-assimilating yeast strain. Appl Microbiol Biotechnol. 2006 Oct;72(6):1136-43. DOI:10.1007/s00253-006-0402-x |

- Bro C, Regenberg B, Förster J, and Nielsen J. In silico aided metabolic engineering of Saccharomyces cerevisiae for improved bioethanol production. Metab Eng. 2006 Mar;8(2):102-11. DOI:10.1016/j.ymben.2005.09.007 |

- Hill J, Nelson E, Tilman D, Polasky S, and Tiffany D. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc Natl Acad Sci U S A. 2006 Jul 25;103(30):11206-10. DOI:10.1073/pnas.0604600103 |

- Zhang YH, Evans BR, Mielenz JR, Hopkins RC, and Adams MW. High-yield hydrogen production from starch and water by a synthetic enzymatic pathway. PLoS One. 2007 May 23;2(5):e456. DOI:10.1371/journal.pone.0000456 |

-

=

-

=

-

=

Papers baby wants

- Lu TK and Collins JJ. Dispersing biofilms with engineered enzymatic bacteriophage. Proc Natl Acad Sci U S A. 2007 Jul 3;104(27):11197-202. DOI:10.1073/pnas.0704624104 |

Used in paper already

- Keane A, Phoenix P, Ghoshal S, and Lau PC. Exposing culprit organic pollutants: a review. J Microbiol Methods. 2002 Apr;49(2):103-19. DOI:10.1016/s0167-7012(01)00382-7 |

Bacterial plastics

- Ward PG, Goff M, Donner M, Kaminsky W, and O'Connor KE. A two step chemo-biotechnological conversion of polystyrene to a biodegradable thermoplastic. Environ Sci Technol. 2006 Apr 1;40(7):2433-7. DOI:10.1021/es0517668 |

- Liu SJ and Steinbüchel A. A novel genetically engineered pathway for synthesis of poly(hydroxyalkanoic acids) in Escherichia coli. Appl Environ Microbiol. 2000 Feb;66(2):739-43. DOI:10.1128/AEM.66.2.739-743.2000 |

Chronology of biosensors

1990

1991

1992

1993

1994

Pentachlorophenol

- Van Dyk TK, Majarian WR, Konstantinov KB, Young RM, Dhurjati PS, and LaRossa RA. Rapid and sensitive pollutant detection by induction of heat shock gene-bioluminescence gene fusions. Appl Environ Microbiol. 1994 May;60(5):1414-20. DOI:10.1128/aem.60.5.1414-1420.1994 |

1995

1996

1997

1998

1999

2000

2001

2002

Endocrine disrupting chemicals (EDCs)

- Gu MB, Min J, and Kim EJ. Toxicity monitoring and classification of endocrine disrupting chemicals (EDCs) using recombinant bioluminescent bacteria. Chemosphere. 2002 Jan;46(2):289-94. DOI:10.1016/s0045-6535(01)00081-9 |

Herbicides

- Shao CY, Howe CJ, Porter AJ, and Glover LA. Novel cyanobacterial biosensor for detection of herbicides. Appl Environ Microbiol. 2002 Oct;68(10):5026-33. DOI:10.1128/AEM.68.10.5026-5033.2002 |

Genotoxic agents -- MMC, MNNG, NA

- Weisweiler P and Schwandt P. Biological action of the lipotrophic peptides A and B from pig pituitary glands. Acta Endocrinol (Copenh). 1975 May;79(1):34-42. DOI:10.1530/acta.0.0790034 |

2003

2004

2005

Chlorinated aliphatic hydrocarbons (CAHs) -- trichloroethene (TCE) in ground water

- Bhattacharyya J, Read D, Amos S, Dooley S, Killham K, and Paton GI. Biosensor-based diagnostics of contaminated groundwater: assessment and remediation strategy. Environ Pollut. 2005 Apr;134(3):485-92. DOI:10.1016/j.envpol.2004.09.002 |

2006

Heavy metals

- Shao CY, Howe CJ, Porter AJ, and Glover LA. Novel cyanobacterial biosensor for detection of herbicides. Appl Environ Microbiol. 2002 Oct;68(10):5026-33. DOI:10.1128/AEM.68.10.5026-5033.2002 |

2007

Figures

Example of Abstraction Hierarchy. The oscillator system is composed of three inverter devices, each of which is composed of a ribosome binding site part, a protein coding part, terminator parts, and a regulatory part. DNA-level researchers need only be concerned with creating a specific DNA sequence; part-level researchers need only be concerned with designing DNA sequences with a certain functionality; device-level researchers need only be concerned with combining existing parts to achieve a certain input-output response; and system-level researchers need only be concerned with combining existing devices to build a system with certain behaviors.

- Sørensen SJ, Burmølle M, and Hansen LH. Making bio-sense of toxicity: new developments in whole-cell biosensors. Curr Opin Biotechnol. 2006 Feb;17(1):11-6. DOI:10.1016/j.copbio.2005.12.007 |

Text

Biodegradable Plastics

Since synthetic polymers were first commercialized in the 1920s, they have found application in nearly every aspect of modern day life, including bags, hard containers, electronics, wrappings, foam, laminated paper, fabrics, and many other everyday items. In 1991 alone, fifteen billion pounds of polyethylene were consumed in the United States (chum91).

While cheap and versatile, synthetic polymers are becoming a significant environmental hazard because they can take many years (up to several hundred) years to degrade naturally in landfill. Furthermore, synthetic polymers are typically derived from petroleum, a quickly diminishing resource that incurs significant environmental costs during extraction. For these reasons, there is a real need to produce biodegradable polymers from renewable resources.

Among several potentially viable biodegradable polymers, polyhydroxyalkanoates (PHAs) are especially promising because they can be produced in vivo by several species of microorganisms. Since polymers are commodity materials (i.e. highly cost competitive), biodegradable polymers must be priced comparably with synthetic polymers in order to survive on the marketplace. Synthetic biology can help by increasing the PHA yield from microorganisms and facilitating easier PHA extraction from the microorganisms.

Several species of bacteria––e.g. some in the archaebacterial family Halobacteriaceae (Hezayen02)--accumulate PHA granules when they experience a stress condition involving a nutrient imbalance such as excess carbon ((Anderson and Dawes, 1990, Steinbüchel, 1991 and Steinbüchel and Füchtenbusch, 1998)). However, since natural producers of PHAs tend to grow slowly, introducing PHA accumulation capabilities (i.e. genes encoding PHA synthase and other necessary enzymes) into a fast growing organism such as E. coli raises the overall yield rate and thereby lowers the cost of the polymer. And while engineered plant hosts may be more cost-effective for large scale PHA production because they collect energy from the sun and carbon from air, microbial systems offer more options for polymer composition and carbon source (e.g. polystyrene [ward06]) (aldor03).

PHA synthesis in microbes involves only a few enzymes (Fig. X [aldor03]). Genes encoding these enzymes can be introduced to recombinant bacteria from a number of organisms (Fig. X2 [suri07]). In the simplest pathway, the phaA gene encodes the enzyme, beta-ketothiolase, for the condensation of a pair of acetyl-CoA molecules to form acetoacetyl-CoA, which is then reduced to (R)-3-hydroxyacyl-CoA by the NADPH-cofactor-dependent acetoacetyl-CoA reductase encoded by the phaB gene. Lastly, the phaC gene encoded PHA synthase catalyzes the polymerization of (R)-3-hydroxyacyl-CoA monomers to PHA (aldor03).

Other pathways to supply (R)-3-hydroxyacyl-CoA monomers for PHA synthesis include fatty acid beta-oxidation, as found in bacteria such as P. oleovorans and P. fragii; and fatty acid de novo synthesis, as found in bacteria such as P. aeruginosa and P. putida. Both pathways have been successfully implemented in recombinant E. coli to allow for high rate production of various PHAs and PHA copolymers (suri07).

Mass-produced bacterial and plant-derived PHAs such as MIrel by Metabolix are just beginning to find commercial use. As synthetic biology matures and becomes more widely used in the engineering of biopolymers, we may see significant cost reductions and greater use of biodegradable polymers. In addition, advances in synthetic biology may also lead to the creation of useful metabolic and enzymatic pathways for the degradation and recycling of polymer wastes.

Educational Initiatives

One significant result of synthetic biology is the democratization of bioengineering. Efforts in improving the abstraction, decoupling, and standardization of bioengineering have enabled novice researchers (even high school students) to create and utilize biological parts, devices, and systems.

In 2003, students at MIT participated in a month-long bioengineering mini course and created oscillator systems coupled to fluorescent reporters. The surprising success of this program led to the NSF-sponsored Synthetic Biology Competition (SBC) in 2004, in which five teams from within the United States designed and built genetically encoded machines using standard, interchangeable biological parts. The flagship product of this competition was UT Austin's biological photographic film, a biofilm with bacteria containing a light-detection device that produces PoPS in the presence of photons, as well as a reporting device that produces color in response to the PoPS. The light-detection device was created by combining a new light-detecting part (a bioengineered two-component signaling protein based on cph1 from Synechocystis) with a pre-existing BioBrick part; and the reporting device was created by combining three existing BioBricks parts.

To encourage further student participation in synthetic biology, researchers Drew Endy, Thomas Knight, and Randy Rettberg founded the international Genetically Engineered Machine (iGEM) competition in 2005, which in its first year involved thirteen teams competing from four countries. Through media publicity and rigorous outreach efforts by the competition's staff, iGEM 2006 had 37 teams from fifteen countries develop biological systems and present their results at a judged "Jamboree" event at MIT. To this date, 57 teams have registered to compete in iGEM 2007. Furthermore, several universities have initiated synthetic biology related courses, labs, and iGEM-style mini competitions.

Among the 37 projects in iGEM 2006, four were environmental applications of synthetic biology. Prairie View A&M University took steps towards a metal contamination detection; Mississipi State Univerity designed a hydrogen detecting part for future use in hydrogen-producing bacteria; EGE University (Turkey) attempted to optimize a hydrogen-producing pathway in extremophilic bacteria; and the University of Edinburgh built an arsenate whole cell biosensor that gives a pH response which can be inexpensively read by methyl red or an electronic pH meter. The Edinburgh team's project was particularly interesting because they were able to design a complex system, test it in silico, and construct a simplified prototype for proof-of-concept.

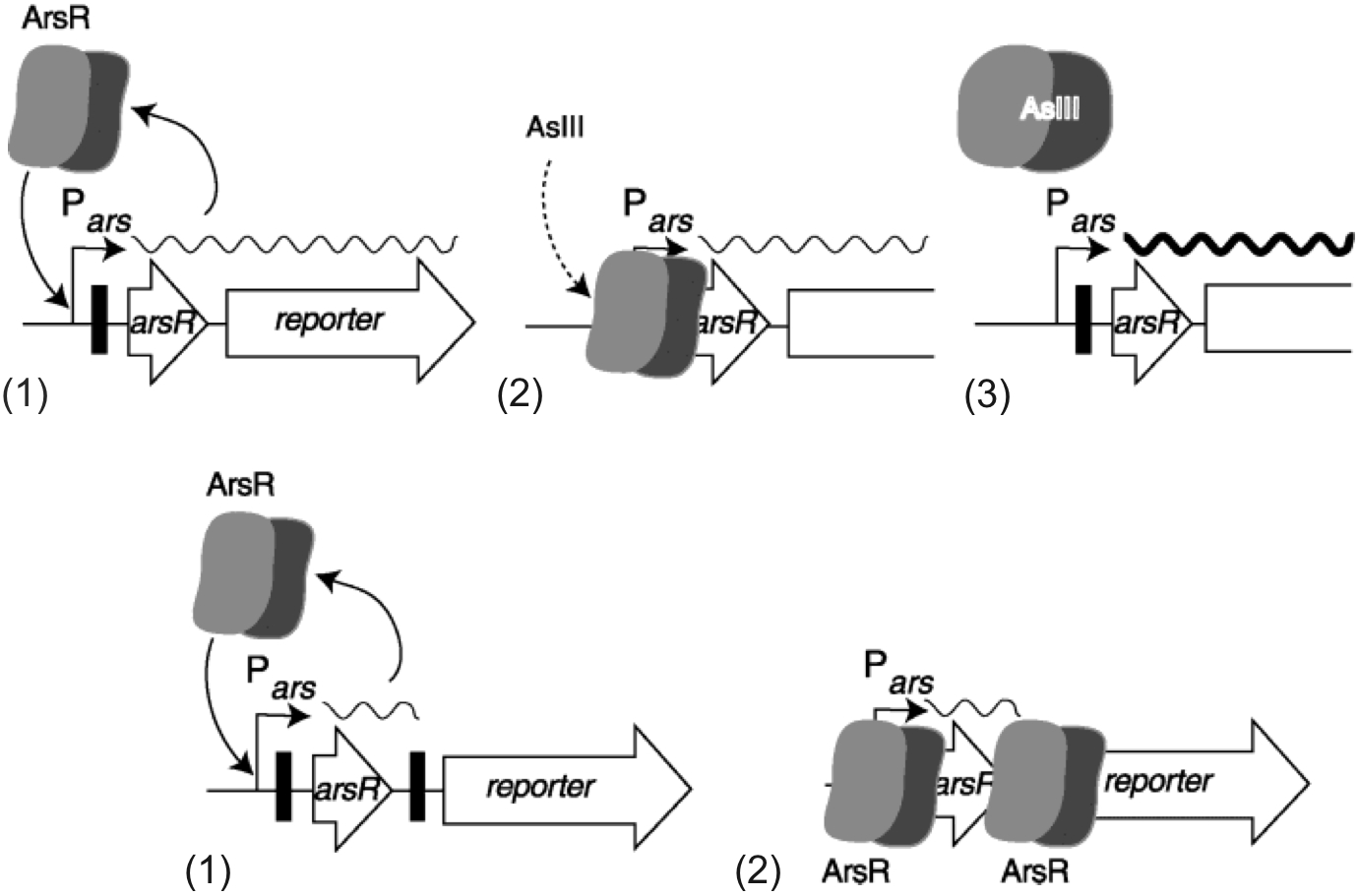

To achieve high detection sensitivity and accuracy over a wide range of sample concentrations, the team used a plasmid-encoded arsenic resistance operon controlled by two repressor proteins, ArsD and ArsR, which respond to high and low concentrations of arsenate, respectively. An increase in pH is induced by urease (expressed from a hybrid promoter repressed by both lambda cI and LacI repressors), which breaks down urea to introduce ammonium ions; while a decrease in pH is achieved by lacZ, which encodes an enzyme that begins the fermentation of lactose to acid products.

In the presence of lactose (added to activate the system) and absence of arsenate, urease is induced to raise the pH. At low arsenate concentrations, the ArsR-repressed promoter is induced, leading to lambda cI repressor expression, which shuts down the production of urease to give near-neutral pH. Finally, at high arsenate concentrations, the ArsD-responsive promotor induces lacZ expression, lowering the pH.

The biosensor system was modeled in silico by eighteen ordinary differential equations, with gene expression reactions modeled by a Michaelis-Menten equation and the other reactions modeled by mass-action equations found in literature. This effort confirmed the system's functionality (at least in theory) and identified the most influential kinetic parameters (e.g. the degradation rate of ArsD).

A laboratory proof-of-concept construct was built by constructing a biobrick part containing the E. coli chrososomal ars promoter and a negatively autoregulated arsR gene, constructing another biobrick part based on the lacZ’ gene (encoding the N-terminus of lacZ, which complements a mutation found on the chromosome of laboratory E. coli), and combining the two parts. This prototype achieved a pH response to arsenate concentrations as low as 5 ppb arsenic, well below the World Health Organization's limit for acceptable drinking water (10 ppb).

http://www.igem2006.com/jamboree.htm http://parts2.mit.edu/wiki/index.php/Edinburgh_summary_page http://parts2.mit.edu/wiki/index.php/EdinburghModeling

Energy Applications

The need for alternative fuels has increased considerably in the recent years due to rising fossil fuel prices and worldwide attention towards environmental sustainability (hill06). While battery technology has steadily progressed, electrochemical energy storage still cannot (and may never) compete with liquid or gaseous fuels on energy density.

Among the promising candidates for alternative fuels are biofuels and hydrogen. Biofuels -- fuels produced from crop-based carbohydrates -- include bioethanol from fermentable sugars of corn or switchgrass, and biodiesel from plant oils (torney07). To improve biofuel production, numerous groups have employed recombinant and metabolic engineering to develop microorganisms that convert carbohydrates from a variety of feedstocks into biofuels. For example, a recombinant Saccharomyces yeast strain has been engineered to break down cellulose and ferment ethanol from xylose, a pentose commonly found in renewable lignocellulosic biomass such as waste paper. This was achieved by introducing genes from P. stipitis and S. cerevisiae for their xylose-fermenting ability, and displaying on the cell surface a cellooligosaccharide-degrading fusion protein from an A. aculeatus gene and α-agglutinin (katahira06). Commercial entities pursuing biofuel applications of synthetic biology include California startups Amyris Biotechnologies, LS9, and Synthetic Genomics.

Using a different synthetic biology approach to produce hydrogen gas, Zhang et al created a synthetic enzymatic pathway employing thirteen enzymes from rabbit muscle, spinach, and three strains of bacteria (S. cerevisiae, E. Coli, P. furiosus) to convert starch and water into hydrogen and carbon dioxide, as summarized in Table X (zhang07).

The resulting spontaneous (ΔG°= -48.9 kJ/mol), slightly endothermic (ΔH°= 595.6 kJ/mol) overall reaction

C6H10O5 (l) + H2O (l) ⇒ 12 H2 (g) + 6 CO2 (g)

occurred at 30°C under atmospheric pressure and yielded more hydrogen than the theoretical yield of biological hydrogen fermentation (12 versus 4 H2/glucose).

This synthetic enzymatic approach has important advantages over chemical catalysis for hydrogen production, including lower toxicity, milder reaction conditions, less stringent infrastructural requirements, and better economics from using starch as the feedstock. Furthermore, when compared with microbial approaches, synthetic enzymatic pathways have higher product yield, easier implementation and controls, no formation of by-products and cell mass, and broader reaction conditions (i.e. wider temperature and pH ranges). It is anticipated that cell-free synthetic enzymatic pathways will eventually replace chemical catalysis and microorganisms in the production of many commodity chemicals (zhang07).

This synthetic enzymatic approach has important advantages over chemical catalysis for hydrogen production, including lower toxicity, milder reaction conditions, less stringent infrastructural requirements, and better economics from using starch as the feedstock. Furthermore, when compared with microbial approaches, synthetic enzymatic pathways have higher product yield, easier implementation and controls, no formation of by-products and cell mass, and broader reaction conditions (i.e. wider temperature and pH ranges). It is anticipated that cell-free synthetic enzymatic pathways will eventually replace chemical catalysis and microorganisms in the production of many commodity chemicals (zhang07).

Some individuals--including Craig Venter, founder of The Institute for Genomic Research, the J. Craig Venter Institute for genomic research, and Synthetic Genomics--consider energy the most pressing issue on the planet today. Enormous challenges exist for producing high energy fuel inexpensively and without occupying too much fertile land. Fortunately, synthetic biology has recently matured enough to address some of these critical challenges. Given the existence of a variety of carbon-containing feedstock, metabolic and enzymatic pathways, genetically modifiable organisms, and R&D funding sources, we can expect a significant amount of biological innovation to come from the energy sector within the next decade.

- Torney F, Moeller L, Scarpa A, and Wang K. Genetic engineering approaches to improve bioethanol production from maize. Curr Opin Biotechnol. 2007 Jun;18(3):193-9. DOI:10.1016/j.copbio.2007.03.006 |

- Katahira S, Mizuike A, Fukuda H, and Kondo A. Ethanol fermentation from lignocellulosic hydrolysate by a recombinant xylose- and cellooligosaccharide-assimilating yeast strain. Appl Microbiol Biotechnol. 2006 Oct;72(6):1136-43. DOI:10.1007/s00253-006-0402-x |

- Zhang YH, Evans BR, Mielenz JR, Hopkins RC, and Adams MW. High-yield hydrogen production from starch and water by a synthetic enzymatic pathway. PLoS One. 2007 May 23;2(5):e456. DOI:10.1371/journal.pone.0000456 |

http://www.msnbc.msn.com/id/18882837/site/newsweek/

How 'Synthetic' is Environmental Synthetic Biology?

The current state of knowledge in biology has enabled researchers to work principally within one level of the abstraction hierarchy to engineer novel organisms. For example, a biological input-output device can be created by taking an output part from one organism (e.g. the GFP gene from jellyfish [Nature425]), and input part from another (e.g. an olfactory receptor from a mammalian cell [Pajot-Augy03]), and integrating those parts into a chassis of choice (e.g. yeast cells). This sort of genetic plug-and-play can in some cases be done without fully understanding the operational mechanisms of all the parts.

However, the lack of standardization of biological parts and devices has impeded research progress by requiring researchers to devote a significant portion of their efforts to interface engineering -- that is, assembling the many parts and getting them to function together predictably. Standardization would reduce costly inefficiencies by simplifying both the design and construction stages of bioengineering and minimizing the amount of experimental guesswork needed.

Furthermore, as bioconstruction technologies advance, synthetic biology research activities can be expected to progress at higher rates and become much more widespread. While researchers today can purchase made-to-order DNA cheaply, most of the necessary bioengineering steps (e.g. making fusion proteins,XXXXXXXXXXXX) must still be done laboriously by hand. Decoupling design and construction in bioengineering would allow individuals to innovate without having to work in expensive wet lab facilities at all times. Just as online machine shop services have enabled individuals to order custom-designed parts to create innovative products from their home, the further decoupling of biological design and construction (e.g. providing the ability to order custom-designed organisms rather than just fragments its DNA) will allow synthetic biologist to create and experiment with useful biological systems at lower costs. Perhaps more importantly, the decoupling would enable a greater number of individuals (of various levels of experience) to utilize synthetic biology for solving a variety of real world problems.

In the following sections, the current state of environmental synthetic biology is summarized. It shall be apparent that most of the work involve creating whole cell sensors that contain a reporter (e.g. coding for GFP or luciferase) and a promoter inducible by environmental toxins. These projects can be considered device-level engineering, as the resulting product is usually a simple input-output device. Examples of system-level engineering for environmental applications is only starting to appear...

Non-relevant

Calculating relative centrifugal force (RCF)

Relative centrifugal force is the measurement of the force applied to a sample within a centrifuge. This can be calculated from the speed (RPM) and the rotational radius (cm) using the following calculation.

- g = RCF = 0.00001118 × r × N2

where

- g = Relative centrifuge force

- r = rotational radius (centimetre, cm)

- N = rotating speed (revolutions per minute, r/min)

Links

Title:

Selective Fractionation of Nanowire Diameter by Centrifugation

Authors:

Trammell, T. E.

Publication:

American Physical Society, APS March Meeting, March 21-25, 2005, abstract #V25.005

Publication Date:

03/2005

http://www.coleparmer.com/techinfo/techinfo.asp?htmlfile=basic-centrifugation.htm&ID=30